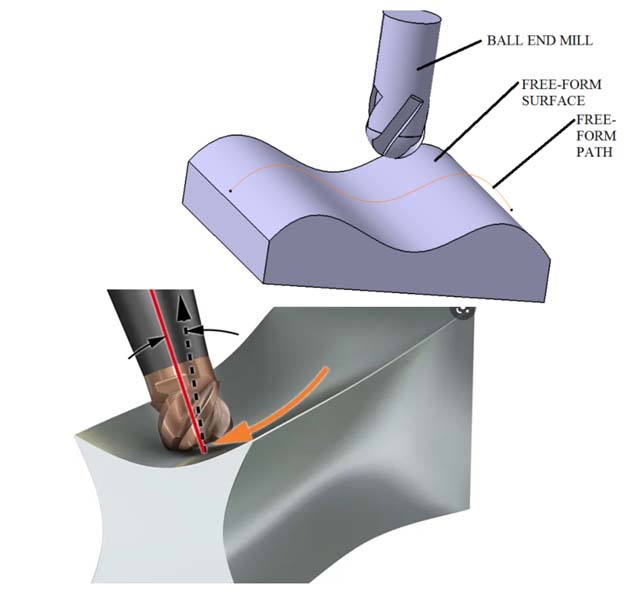

Maloya is proud to announce it is upgrading its CNC metal milling capabilities. Until recently, the Maloya team has done traditional 3-axis CNC programming. While this type of CNC programming served us well in the past to accomplish our basic tasks of machining, our team was unable to accept certain projects which required more than just linear X,Y,Z motions. In aerospace and design applications our expert sales and quoting team was seeing a growing demand for more sophisticated machining applications. With this in mind, the Maloya executive team made the investment in the Mastercam Mill 3D upgrade. This new and advanced capability allows our team to take on surfacing applications where we can incorporate non-linear tool paths to produce features having curvature.

Surfacing Examples in Metal

In addition to the new machining capability, this Mill 3D software version also makes programming metal projects much more automated and efficient.

These are a few examples of the new features in Mill 3D for metals:

- Automatic 3+2 Roughing

- Dynamic Motion toolpaths (3D)

- Full multisurface and solid roughing metals

- Full multisurface and solid finishing metals

- Full multisurface and solid optimized roughing metals

- Full multisurface and solid high-speed machining metals

- Full multisurface and hybrid finishing metals

Videos

These videos demonstrate the benefits of the improved efficiency of the 3D Mill tool path capability.

Do you have a project that requires advanced, non-linear machining applications? Contact us or request a quote.

.png?width=80&name=Untitled%20design%20(37).png)